|

|

| Brand Name: | Benenv |

| Model Number: | Standard DAF |

| MOQ: | 1 Set |

| Price: | Negotiatable |

| Delivery Time: | 5-8 weeks |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

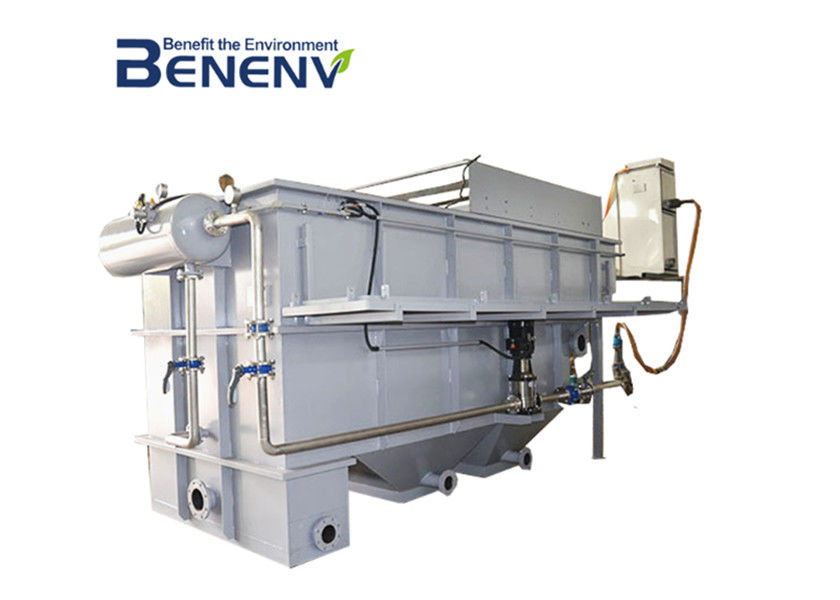

Packaged Clarifier Sludge Scraper Dissolved Air Flotation (DAF) Equipment

Brief Introduction of Dissolved Air Flotation

![]()

Parameter

The dimensions and other information of Benenv dissolved air flotation are as follows:

![]()

| Model | Productivity (m3/h) | Water volume (m3/h) | Power (kw) | Blows form machine power (kw) | Air flotation pot specification (mm) |

| XRWF-11-5 | 4-5 | 1.5-2 | 3 | 0.75 | φ400×1000 |

| XRWF-11-10 | 8-10 | 2-3 | 3 | 0.75 | φ500×1512 |

| XRWF-11-15 | 10-16 | 3-4 | 3 | 0.75 | φ500×1512 |

| XRWF-11-20 | 15-20 | 5-7 | 7.5 | 1.1 | φ500×1512 |

| XRWF-11-30 | 20-30 | 6-10 | 7.5 | 1.1 | φ500×1512 |

| XRWF-11-40 | 30-40 | 8-13 | 7.5 | 1.1 | φ600×1880 |

| XRWF-11-50 | 40-50 | 15-20 | 7.5 | 1.5 | φ600×1880 |

| XRWF-11-60 | 50-60 | 18-27 | 7.5 | 1.5 | φ600×1880 |

| XRWF-11-80 | 70-80 | 24-32 | 7.5 | 1.5 | φ650×2034 |

| XRWF-11-105 | 90-105 | 30-35 | 15 | 1.5 | φ700×1980 |

| XRWF-11-150 | 125-150 | 60-80 | 22 | 2.2 | φ800×1980 |

| XRWF-11-200 | 175-200 | 80-100 | 22 | 3 | φ800×2100 |

| XRWF-11-250 | 225-250 | 110-120 | 22 | 3 | φ800×2400 |

| XRWF-11-300 | 280-300 | 120-180 | 37 | 3 | φ1000×2900 |

Working principle of DAF dissolved air flotation unit:

The feed water of alum plant wasterwater to DAF dissolved air flotation tank is often (but not always) dosed with a coagulant (such as ferric chloride or aluminum sulfate) to coagulate the colloidal particles and/or flocculants to conglomerate the particles into bigger clusters.

A portion of clarified effluent water leaving the DAF dissolved air flotation tank is pumped into a small pressure vessel (called air drum or saturator) into which compressed air is also introduced. This process saturates pressurized effluent water with air under pressure (2.5~4kg/cm2).

1. Micro bubble generation

2. Sedimentation technology

3. Counter current mechanism

4. Scum circulation and flocculation technology

5. Hypo-surface capture technology

6. Laminar flow in separation zone technology

![]()

Packing and Delivery

1. The normal package is wooden box(Size: L*W*H). If export to European countries,the wooden box will be fumigated.If container is too tighter,we will use pe film for packing or pack it according to customers special request.

2. We also support 20',40' container delivery, use soft packaging to protect machine well. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

![]()

FAQ:

Q: Are You Trading Company Or Manufacture?

A: We Are Both Manufacture And Trading Company. We Have Over 30 Years' Professional Experience As a Waste Water Treatment Equipment Manufacturer And Engineering Service Enterprise.

Q : What Are Your Main Products?

A:Keywords :Sludge Dewatering Machine Equipment, Screw Type Sludge Dewatering Press Sludge Screw Press, Dewatering Sludge Machine Screw Press ,Sewage Treatment Equipment ,Sludge Treatment Plant,Screw Press Sludge Dewatering ,Dewatering Sludge,Dewatering Machine For Sludge, Dewatering Sludge Machine Screw Press, Rotary Drum Bar Screens, Equipment DAF, DAF Price ,Dissolved Air Flotation System Price, Sludge Shaftless Screw Conveyor,Chemical Dosing Device ,MBBR Price,MBBR Media,Disc Diffuser, Polymer Preparation Chemical Dosing System,

Q: How Can I Find The Suitable Model?

A: Please Provide Flow Rate, Solids Content And Sludge Type, We Can Assist You In Model Selection.

Q: Where Is Your Factory Located?

A: Yixing City, We are in the famous city of environmental protection equipment ,professional for Sludge screw press dewatering Machine ,Which Is Very Close To Shanghai With Only Less Than 3 Hours' Driving. Welcome for your visiting.

Q: Do You Provide OEM Service?

A: Yes. We Can Do The Customized Design According To Your Different Request for sludge Dewatering.

Q: How About The Production Capacity Of Your Company?

A: Our Factory Covers Area Over 22,000M2 And Produces Machines 2000 Sets Per Year.

Q: How Could We Trust You And Your Company? Is This Your First Time Transaction?

A: A: Our Company Has More Than 30 Years Professional Experience. We Cooperate Over 1000 Customers.In China And Overseas. We Export Nearly 60 Countries All Over The World.And We Have More Than 60+Patents, CE,ISO 9001,SGS Certificates. And We Have Company In Japan , Great Technology And Great Quality.

Q: Do You Offer After-Sales Service?

A: Video Technical Support, Online Support,Spare Parts,Field Maintenance Repair Service

Q: How Long is Your Warranty?

A: 2 Years After The Arrival Of The Goods. During This Period, As Long As It Is Not a Man-Made Damage, We Send The Damaged Parts Free Of Charge.

Q: What About Your Produce Time?What Kind Of Transportation Do You Offer?

A:Within 30 Days Against Down Payment. Air, Land & Sea .

Q: What Kind Of Payment Do You Accept?

A: T/T, L/C, Paypal, Cash, D/P, D/A, Western Union, Money Gram

|

| Brand Name: | Benenv |

| Model Number: | Standard DAF |

| MOQ: | 1 Set |

| Price: | Negotiatable |

| Packaging Details: | Wooden Package for dissolved air flotation |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

Packaged Clarifier Sludge Scraper Dissolved Air Flotation (DAF) Equipment

Brief Introduction of Dissolved Air Flotation

![]()

Parameter

The dimensions and other information of Benenv dissolved air flotation are as follows:

![]()

| Model | Productivity (m3/h) | Water volume (m3/h) | Power (kw) | Blows form machine power (kw) | Air flotation pot specification (mm) |

| XRWF-11-5 | 4-5 | 1.5-2 | 3 | 0.75 | φ400×1000 |

| XRWF-11-10 | 8-10 | 2-3 | 3 | 0.75 | φ500×1512 |

| XRWF-11-15 | 10-16 | 3-4 | 3 | 0.75 | φ500×1512 |

| XRWF-11-20 | 15-20 | 5-7 | 7.5 | 1.1 | φ500×1512 |

| XRWF-11-30 | 20-30 | 6-10 | 7.5 | 1.1 | φ500×1512 |

| XRWF-11-40 | 30-40 | 8-13 | 7.5 | 1.1 | φ600×1880 |

| XRWF-11-50 | 40-50 | 15-20 | 7.5 | 1.5 | φ600×1880 |

| XRWF-11-60 | 50-60 | 18-27 | 7.5 | 1.5 | φ600×1880 |

| XRWF-11-80 | 70-80 | 24-32 | 7.5 | 1.5 | φ650×2034 |

| XRWF-11-105 | 90-105 | 30-35 | 15 | 1.5 | φ700×1980 |

| XRWF-11-150 | 125-150 | 60-80 | 22 | 2.2 | φ800×1980 |

| XRWF-11-200 | 175-200 | 80-100 | 22 | 3 | φ800×2100 |

| XRWF-11-250 | 225-250 | 110-120 | 22 | 3 | φ800×2400 |

| XRWF-11-300 | 280-300 | 120-180 | 37 | 3 | φ1000×2900 |

Working principle of DAF dissolved air flotation unit:

The feed water of alum plant wasterwater to DAF dissolved air flotation tank is often (but not always) dosed with a coagulant (such as ferric chloride or aluminum sulfate) to coagulate the colloidal particles and/or flocculants to conglomerate the particles into bigger clusters.

A portion of clarified effluent water leaving the DAF dissolved air flotation tank is pumped into a small pressure vessel (called air drum or saturator) into which compressed air is also introduced. This process saturates pressurized effluent water with air under pressure (2.5~4kg/cm2).

1. Micro bubble generation

2. Sedimentation technology

3. Counter current mechanism

4. Scum circulation and flocculation technology

5. Hypo-surface capture technology

6. Laminar flow in separation zone technology

![]()

Packing and Delivery

1. The normal package is wooden box(Size: L*W*H). If export to European countries,the wooden box will be fumigated.If container is too tighter,we will use pe film for packing or pack it according to customers special request.

2. We also support 20',40' container delivery, use soft packaging to protect machine well. If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

![]()

FAQ:

Q: Are You Trading Company Or Manufacture?

A: We Are Both Manufacture And Trading Company. We Have Over 30 Years' Professional Experience As a Waste Water Treatment Equipment Manufacturer And Engineering Service Enterprise.

Q : What Are Your Main Products?

A:Keywords :Sludge Dewatering Machine Equipment, Screw Type Sludge Dewatering Press Sludge Screw Press, Dewatering Sludge Machine Screw Press ,Sewage Treatment Equipment ,Sludge Treatment Plant,Screw Press Sludge Dewatering ,Dewatering Sludge,Dewatering Machine For Sludge, Dewatering Sludge Machine Screw Press, Rotary Drum Bar Screens, Equipment DAF, DAF Price ,Dissolved Air Flotation System Price, Sludge Shaftless Screw Conveyor,Chemical Dosing Device ,MBBR Price,MBBR Media,Disc Diffuser, Polymer Preparation Chemical Dosing System,

Q: How Can I Find The Suitable Model?

A: Please Provide Flow Rate, Solids Content And Sludge Type, We Can Assist You In Model Selection.

Q: Where Is Your Factory Located?

A: Yixing City, We are in the famous city of environmental protection equipment ,professional for Sludge screw press dewatering Machine ,Which Is Very Close To Shanghai With Only Less Than 3 Hours' Driving. Welcome for your visiting.

Q: Do You Provide OEM Service?

A: Yes. We Can Do The Customized Design According To Your Different Request for sludge Dewatering.

Q: How About The Production Capacity Of Your Company?

A: Our Factory Covers Area Over 22,000M2 And Produces Machines 2000 Sets Per Year.

Q: How Could We Trust You And Your Company? Is This Your First Time Transaction?

A: A: Our Company Has More Than 30 Years Professional Experience. We Cooperate Over 1000 Customers.In China And Overseas. We Export Nearly 60 Countries All Over The World.And We Have More Than 60+Patents, CE,ISO 9001,SGS Certificates. And We Have Company In Japan , Great Technology And Great Quality.

Q: Do You Offer After-Sales Service?

A: Video Technical Support, Online Support,Spare Parts,Field Maintenance Repair Service

Q: How Long is Your Warranty?

A: 2 Years After The Arrival Of The Goods. During This Period, As Long As It Is Not a Man-Made Damage, We Send The Damaged Parts Free Of Charge.

Q: What About Your Produce Time?What Kind Of Transportation Do You Offer?

A:Within 30 Days Against Down Payment. Air, Land & Sea .

Q: What Kind Of Payment Do You Accept?

A: T/T, L/C, Paypal, Cash, D/P, D/A, Western Union, Money Gram